Emergency Cases

Your treatment plan is designed for steady progress, with every phase promptly implemented.

Nanocolltech LLC has developed nano-based coatings designed to cost-effectively tackle critical issues such as corrosion, contamination, and scaling in the oil and gas industry. These solutions significantly improve the productivity, durability, safety, and efficiency of equipment and infrastructure, with the final goal of boosting production volume.

Nanocolltech uses its premier product, NCT-HYGI Coating®, along with its variant designed expressly for the petroleum industry, NCT-Dry®, to directly address key challenges faced in petroleum exploration, extraction, and transportation. NCT-HYGI Coating® is an easy-to-apply solution that offers comprehensive benefits for the oil industry. It not only prevents scaling and corrosion but also addresses issues such as the deposition of paraffin and paraffinic hydrocarbons, common challenges in crude oil production.

During the production of crude oil, the oil extracted may be heavy and viscous, or it might have a high content of paraffinic hydrocarbons. In the production tubing, these heavier hydrocarbons can precipitate, gradually reducing the daily output of crude oil.

Paraffins are typically found in lighter oils, but they can also occur in some heavy oils that have been biodegraded. These paraffinic oils can lead to wax buildup in various parts of the operation, including the reservoir, wellbore, pipelines, and surface facilities, particularly when temperatures fall below the wax appearance temperature (WAT). This accumulation of wax can slow down the flow rate, increase pressure drops, damage equipment, and pose safety risks. Regular wax removal techniques are employed to manage paraffin hydrocarbons, such as mechanical scraping, chemical dissolution, or the circulation of hot oil.

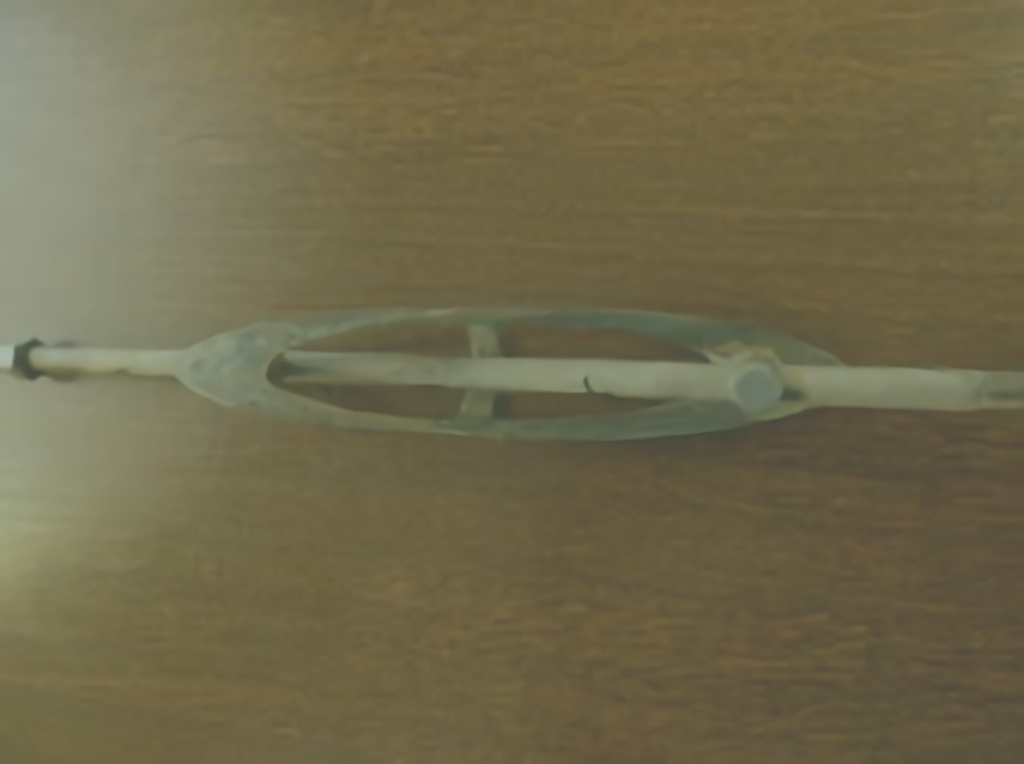

The paraffin removal knife is commonly used in production to clean or eliminate these precipitated parts from the production tubing.

However, cleaning and mobilizing this tool can be both time-consuming and challenging. If the tool is treated with NCT-Dry®, the cleaning process becomes quicker, and it may not need to be cleaned as frequently as before. By using this approach, operators can save both time and money, ultimately reducing production losses.

In addition to reducing the need for maintenance on paraffin removal tools, Nanocolltech’s NCT-Dry®, offer solutions for extending the longevity and efficiency of the oil and gas industry’s key infrastructure. These coatings can be applied to the interiors of pipes and tubing, effectively preventing scaling, clogging, and ensuring optimal flow rates. This is particularly important in maintaining uninterrupted crude oil production, where minor reductions in flow can significantly impact daily output.

Furthermore, NCT-Dry® goes a step further by protecting the equipment used in extracting oil. It prevents corrosion, wear, and other forms of damage, keeping the machinery that’s critical to the process functional and effective. This is especially important in challenging conditions where corrosive elements, such as sulfur compounds found in crude oil, can harm equipment performance and safety.

NCT-Dry® also covers the protection needs of the more exposed parts of oil rigs, including drilling equipment and the structures of offshore platforms. This coating is able to protect these components from conditions at sea, like salt, moisture, and humidity, which are typical challenges in offshore oil production. NCT-Dry® greatly lowers the risk of corrosion, extending their useful life and reducing the need for frequent maintenance.

Easy to Apply

Paraffin removal tool after regular use - uncoated

Paraffin removal tool after regular use - coated

Increased efficiency and reduced downtime of extraction equipment

Protect equipment, tools and infrastructure on offshore sites from scaling and corrosion caused by environmental factors

In the oil production industry, tackling issues with wax buildup and paraffin hydrocarbons is essential for keeping operations smooth and safe. Innovative solutions, such as NCT-Dry® coatings, have proven effective in addressing these challenges. These coatings are used across different sectors within the oil industry, providing several key benefits.

Innovative protective solution designed to address challenges related to wax deposition and paraffin hydrocarbons during crude oil production. This specialized coating acts as a shield, preventing the accumulation of harmful substances, particularly paraffinic hydrocarbons, in various parts of the oil production process, such as production tubing, reservoirs, wellbores, pipelines, and surface facilities.

An economical HVAC solution for processing and logistical centres on transportation routes, ensuring pure and clean air flow in these locations seamlessly.

Comprehensive diagnoses of multiple sclerosis (MS), as well as treatments aimed to prevent further irreversible...

Numerous conservative treatments, as well as invasive treatment involving deep brain stimulation, both aimed to...

Nanocolltech is deeply committed to fostering close collaborations with its partners, ensuring our joint efforts yield the most impactful results. We take pride in crafting tailor-made solutions, specifically designed to meet the unique needs of our clients across various industries.

Zágráb utca 17, 6753,

Szeged, Hungary

sd@nanocolltech.com